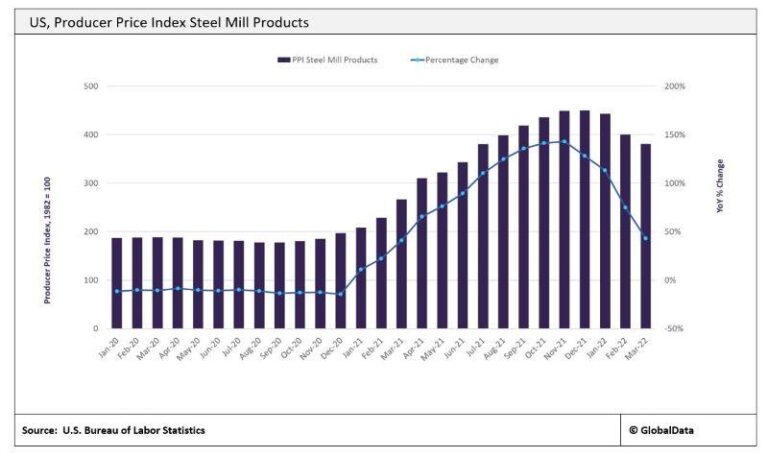

American steel prices have surged sharply in recent months, prompting concern among manufacturers and consumers nationwide. Industry leaders and buyers are pointing to newly imposed tariffs as the primary driver behind the rising costs, which threaten to ripple through various sectors of the U.S. economy. This increase in steel prices comes amid ongoing trade tensions and policy shifts, reigniting debates over the impact of protectionist measures on domestic industries and market competitiveness.

Rising Tariffs Drive Up American Steel Prices Impacting Construction and Manufacturing Sectors

Recent adjustments in trade policy have led to a notable increase in steel tariffs, prompting a ripple effect throughout various American industries.Construction firms are now grappling with rising costs for essential materials, which threaten project budgets and timelines. Meanwhile, manufacturers dependent on steel components face squeezed profit margins and must reconsider supply chain strategies to mitigate the inflationary pressures. Industry insiders emphasize that these tariffs, initially aimed at protecting domestic producers, are inadvertently increasing operational expenses across the board.

Key consequences observed include:

- Higher prices for structural steel and steel-reinforced materials

- Delayed procurement cycles due to increased costs and supply constraints

- Shift in sourcing strategies,with some companies exploring alternative materials

- Potential slowdown in new construction projects and manufacturing expansion

| Sector | Estimated Price Increase (%) | Primary Challenge |

|---|---|---|

| Construction | 12% | Budget overruns |

| Manufacturing | 15% | Supply chain disruptions |

| Automotive | 10% | Component sourcing |

Industry Leaders Cite Trade Policies as Primary Cause of Cost Increases

Executives across the steel industry have uniformly pointed to recent government tariffs as the key driver behind the upward trajectory of steel prices. Many note that these trade policies were intended to protect domestic producers but have inadvertently created a ripple effect, pushing raw material costs higher and squeezing supply chains. Manufacturers and buyers alike report that the tariffs have disrupted established import channels,reducing the availability of competitively priced foreign steel and leaving domestic mills with increased leverage to raise prices.

Industry representatives emphasize several critical impacts:

- Sharp price hikes linked directly to the cost of imported materials

- Reduced market competition, leading to less favorable terms for buyers

- Longer lead times and supply uncertainties affecting project schedules

| Impact Factor | Reported Effect |

|---|---|

| Tariff Rate | 25% |

| Steel Price Increase | Up to 18% |

| Average Delay in Delivery | 3-5 weeks |

Economic Implications of Elevated Steel Prices for Domestic Infrastructure Projects

Rising steel prices have substantially strained budgets for domestic infrastructure projects, forcing many agencies to re-evaluate timelines and scope. The increased cost of raw materials is not only inflating initial outlays but also posing challenges for long-term maintenance forecasts. Contractors and developers report delays as projects are re-scoped to mitigate escalating expenses, while some smaller-scale initiatives face potential cancellation amid tightened fiscal constraints.

Key economic repercussions include:

- Heightened project financing costs due to increased capital requirements

- Potential rise in public borrowing to cover budget shortfalls

- Reduced competitiveness of American steel users compared to global counterparts

- Shift in procurement strategies, with some entities exploring alternative materials

| Project Type | Original Budget | Revised Cost Estimate | Delay Impact |

|---|---|---|---|

| Highway Expansion | $350M | $410M | 6 months |

| Bridge Renovation | $120M | $145M | 4 months |

| Rail Infrastructure | $200M | $245M | 7 months |

Strategies for Buyers to Mitigate the Effects of New Tariff-induced Price Hikes

Buyers facing the recent surge in steel prices are exploring several practical approaches to soften the impact of the new tariffs. Many are turning to strategic sourcing, seeking domestic suppliers who can offer competitive pricing without the additional tariff burden. Others are leveraging bulk purchasing agreements to lock in current prices and avoid future spikes. Additionally, some companies are investing in supply chain diversification, reducing reliance on steel imports by cultivating relationships with regional providers across North America and beyond.

Innovations in product design and materials are also gaining traction, as purchasers look for alternatives to customary steel or ways to use less of it without compromising quality. Industry experts recommend buyers consider:

- Substituting lighter metals such as aluminum or composites where feasible.

- Improving manufacturing efficiency to minimize waste and optimize steel usage.

- Collaborating with suppliers to share risk and identify cost-saving logistics strategies.

| Strategy | Potential Benefit | Implementation Timeframe |

|---|---|---|

| Bulk Purchasing | Price stability | Short-term (1-3 months) |

| Supply Chain Diversification | Reduced risk | Medium-term (3-6 months) |

| Material Substitution | Cost reduction | Long-term (6-12 months) |

Final Thoughts

As American steel prices climb amidst ongoing tariff policies, industry stakeholders and consumers alike face increasing costs that ripple through supply chains nationwide. While the government maintains tariffs aim to protect domestic producers, buyers contend that the higher prices undermine competitiveness and economic recovery efforts. The evolving landscape underscores the complex balance between safeguarding American industries and managing market impacts, a challenge that remains at the forefront of trade policy debates.