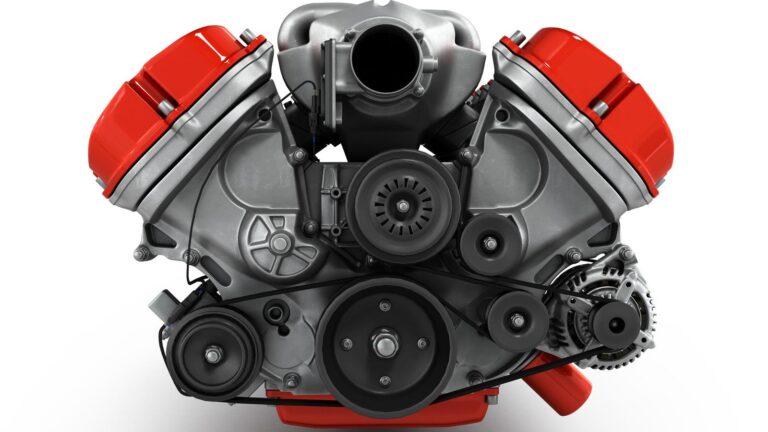

GM Commits $888 Million to Next-Generation V-8 Engine Innovation

General Motors is channeling a substantial investment of $888 million into the creation and manufacturing of an advanced V-8 engine at its New York facility. This initiative highlights GM’s dedication to pushing the boundaries of powertrain technology while sustaining a robust manufacturing footprint within the United States. The new engine aims to deliver enhanced horsepower, improved fuel economy, and lower emissions, positioning GM as a leader in the high-performance vehicle segment.

The project is poised to generate hundreds of new employment opportunities and will incorporate cutting-edge production techniques, such as:

- Utilization of lightweight composite materials to boost engine durability and efficiency

- Refined combustion processes designed to maximize power output while meeting stringent environmental standards

- Modular architecture enabling compatibility across multiple vehicle platforms

Below is an overview of the expected advantages for both GM and the local economy:

| Category | Projected Outcome |

|---|---|

| Employment Growth | Over 400 new manufacturing and engineering roles |

| Production Launch | Scheduled for 2026 |

| Engine Performance | Up to 750 horsepower output |

Revitalizing New York’s Economy with Manufacturing and Workforce Expansion

GM’s $888 million investment to produce its next-generation V-8 engine in New York represents a major economic stimulus for the region’s manufacturing sector. This development is expected to invigorate local industry by increasing demand across supply chains and related fields. The initiative will create hundreds of direct manufacturing jobs and numerous ancillary positions in logistics, engineering, and technical training, thereby enhancing workforce stability and economic resilience.

Highlights of the employment impact include:

- More than 500 direct manufacturing jobs focused on engine assembly and quality assurance

- Over 1,200 indirect roles in supplier networks, transportation, and support services

- Collaborative training programs with local technical colleges to prepare workers for advanced manufacturing careers

| Job Type | Estimated Positions | Employment Duration |

|---|---|---|

| Manufacturing Technicians | 520 | Permanent |

| Supply Chain & Logistics | 350 | Permanent |

| Engineering & Design | 180 | Permanent |

| Apprentices & Trainees | 650 | 2 Years |

Technological Breakthroughs in GM’s Next-Generation V-8 Engine

The upcoming V-8 engine from General Motors is engineered to set new benchmarks in performance and efficiency. Incorporating an advanced combustion system, this engine is projected to deliver up to 15% more horsepower compared to previous models, while complying with the latest emissions regulations.Innovations include enhanced direct fuel injection, optional turbocharging, and the use of lightweight materials, all contributing to improved throttle response and engine longevity.

- Variable Valve Timing: Dynamically adjusts valve operation to optimize power and efficiency across different driving conditions.

- Integrated Start-Stop Technology: Minimizes fuel consumption during idling without compromising performance.

- Advanced Thermal Management: Ensures consistent engine temperatures for enhanced durability and reliability.

| Feature | Advantage |

|---|---|

| Aluminum Lightweight Engine Block | Reduces overall vehicle weight, improving fuel efficiency |

| Variable Valve Timing | Delivers smoother power across the RPM spectrum |

| State-of-the-Art Emission Controls | Ensures compliance with stringent environmental standards |

Strategies to Foster Long-Term Growth in the U.S. Automotive Industry

Sustaining growth in the rapidly evolving automotive market requires continuous investment in advanced powertrain technologies. GM’s $888 million commitment to developing a next-generation V-8 engine in New York exemplifies how innovation combined with regional manufacturing investment can drive economic and technological progress. This approach highlights the necessity of blending high-performance engineering with environmentally responsible production methods to meet increasing consumer and regulatory demands.

Essential strategic priorities include:

- Revamping domestic manufacturing: Building modern facilities that generate employment and support local economies.

- Strengthening research collaborations: Partnering with universities and technology firms to accelerate innovation.

- Balancing legacy and future technologies: Investing in both advanced internal combustion engines and electric vehicle components to serve diverse market needs.

| Focus Area | Expected Outcome | Timeline |

|---|---|---|

| Advanced Combustion Engine Development | Improved performance and fuel efficiency | 2024-2027 |

| Eco-Friendly Manufacturing Practices | Lower emissions and waste reduction | 2024-2030 |

| Workforce Training and Development | Creation of skilled jobs | 2024-2026 |

Conclusion: GM’s Strategic Investment Fuels Innovation and Economic Growth

General Motors’ $888 million investment in a next-generation V-8 engine manufacturing facility in New York highlights the company’s unwavering focus on innovation and manufacturing excellence within the U.S.automotive sector. As consumer preferences shift and technology advances, GM’s strategy of combining customary engine performance with forward-looking development ensures competitiveness and sustainability. This initiative not only promises to create substantial employment opportunities but also strengthens the economic fabric of the region, marking a significant milestone for both GM and the local community.